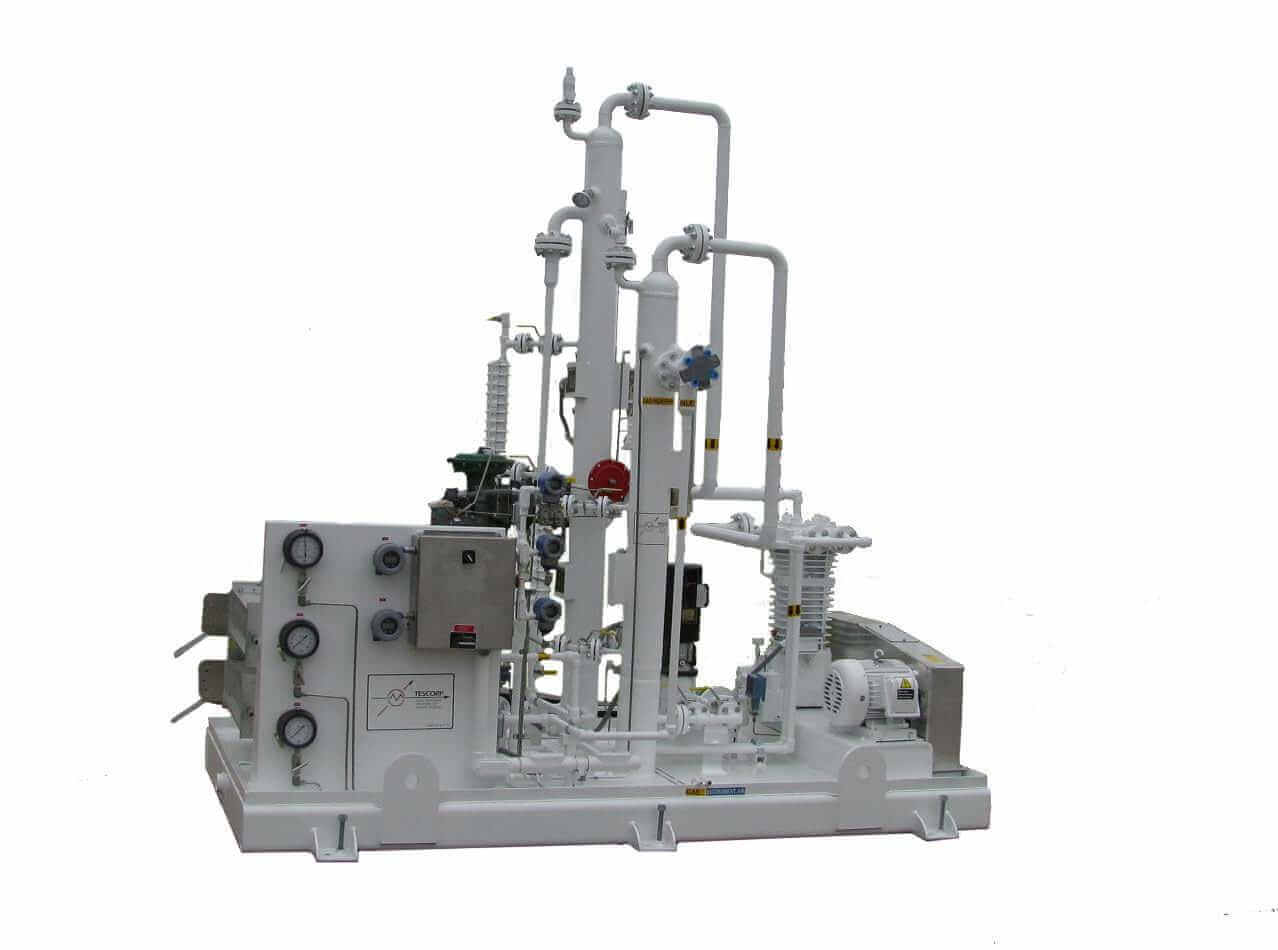

Rotary Vane Compressor Remanufacture

TESCORP, a leading provider of design, builds industrial compression applications and related aftermarket services, has fully staffed offices in Oklahoma. We strive for excellence in customer focus, integrity and prompt attention to your needs.

- Re-Use of Castings allows for lower cost the OEM exchanges

- All Compressors are built to the same exacting factory specs

- Rebuilt Machines come with the same TESCORP quality and warranty you have come to expect over the last 35 years

TESCORP... When Dependable Service is Critical

TESCORP announces NEW compressor manufacturing methods to reduce costs

For over 38 years, TESCORP has been an industry leader in utilizing its field service, engineering and manufacturing capabilities to allow the incorporation of new materials and techniques that were not common before. TESCORP then introduced these same concepts into compressor remanufacturing to gain greater service life at a lower cost than previously experienced through factory authorized exchange programs. TESCORP has expanded its capabilities to include services that were previously restricted by factory contract dictates. These industrial services are recognized techniques that TESCORP has supplied to the demanding oil & gas industry for many years but disallowed by major OEM equipment manufacturers in their quest to supply OEM replacement parts only.

In these difficult economic times, TESCCORP recognizes that the most prudent solution to maintenance issues is a quality repair instead of a much more costly compressor replacement. A high quality restoration using modern manufacturing techniques on the compressor components can restore the service life of the compressor at greatly reduced expense. In addition, TESCORP is able to supply a warranty that meets or exceeds current OEM's offers.

TESCORP was chosen to remanufacture all of the rotary vane compressors at NASA wind tunnel facilities located in the Marshall Space Flight Facility.

TESCORP Platinum Carbon Blades

- Significantly higher temp resistance reduces catastrophic failure

- 4x more wear resistant than kevlar or Phenolic vanes

- Inert to water/moisture so can be stored indefinitely

- Patented process provides superior structural skin strength over other carbon vanes on the market, protecting vanes from delamination

- Higher carbon content provides greater vane integrity

TESCORP Sleeve

On cylinder assemblies that are dramatically out of internal diameter tolerance, TESCORP offers a re-sleeve process to restore the original design dimensions to the cylinder assembly and appropriate performance. This sleeve is manufactured specifically for TESCORP per our standards and specifications out of a harder and more durable iron. The sleeve once installed not only repairs the cylinder, but is stronger with greater tensile strength and less susceptible to wear.

TESCORP Warranty

TESCORP warrants that the new parts installed in your compressor will be free of defects for five (5) years and all remanufactured parts to two (2) years.

Cylinder Remanufacture

The major compressor components that account for the greatest cost in the compressor service are:

- Compressor Cylinder

- Compressor Rotor

- Compressor Heads

These are the components that had little allowable tolerance variation before mandated replacement. In most cases, these components may be repaired and remanufactured back to original tolerances and performance. Remanufacture is a fraction of the cost of replacement.

TESCORP offers the following cylinder service of the extended life of the cylinder assembly without the costly component replacement. Manufacture's standards are that this wear is only acceptable within marginal standards before replacement is called for.

TESCORP Cylinder and Heads Guidelines

OEM Standards

- Minimum length may not be repaired

- Maximum bore may not be connected

- Internal cracks may not be repaired

- Water ports can not be within a 1/8" of a stud hole

- Rotor contact with head

TESCORP Recondition Solution

- Standard length may be restored through metalizing process

- Cylinder may be sleeved to meet original tolerances

- May be repaired through our "metal stitch" process or resleeved

- May be repaired through our "thermo-plastic powder spray" process and milled to original tolerances

- May be metalized back to standard dimensions

TESCORP Rotor Guidelines

OEM Standards

- Minimum length may not be repaired

- Only minimum shaft straightening allowed

- Limited rotor repair allowed

- Limited blade re-slotting allowed

TESCORP Recondition Solution

- Standard length is restored through metalizing and machining

- TESCORP can remanufacture the rotor shaft

- TESCORP re-slots to standard and has additional slot sizing available beyond factory standard for additional service life. TESCORP TES-VANES are required

- TESCORP manufactures and supplies a steel (AISI 4140) rotor for replacement service