Single-stage Vapor Recovery System

20 to 50 Horsepower Systems

Capabilities from 100 to 400 MSCFD

Pressure capabilities up to 95 PSIA

Single-stage Vapor Recovery System

CVR-M (Modular)

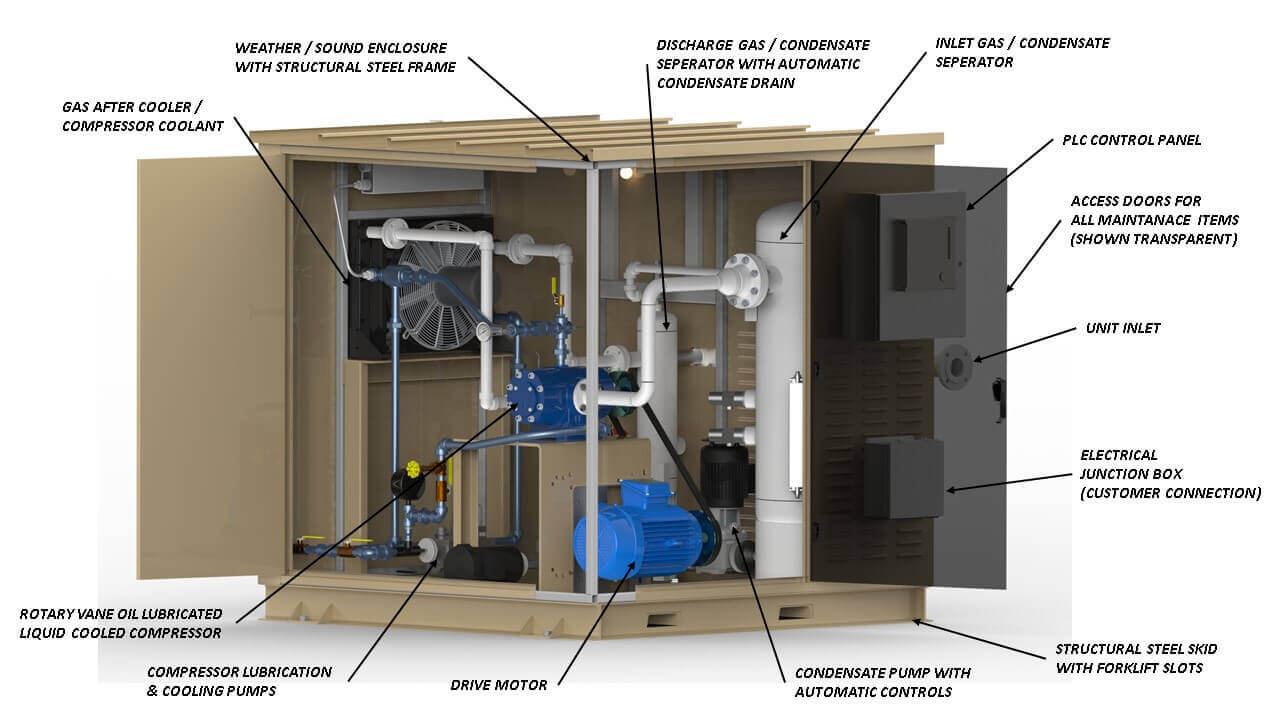

TESCORP “CVR-Mini” Series VRU system for application to meet EPA CFR 40, Subpart 0000 regulations and our customers stock tank vapor recovery gas emission requirements. Designed and constructed for “wet” gas applications utilizing a rugged single-stage rotary vane compressor. TESCORP’s “CVR-M” & “CVR-MH” are compact, self-contained, fully-automated VRU systems complete with gas cooling, “load/no-load” capacity control with sophisticated PLC control logic with customer “DCS” communications.

The unit offers the following design and optional features:

- Liquid cooled, oil-lubricated, single-stage rotary vane compressor utilizing mechanical seals and heads designed for saturated gas applications

- Compressor options include Double-Bellows mechanical seals

- NEC Class I, Div. II, Premium efficiency TEFC 460 VAC/3 Ph. /60Hz electric drive motor. VFD ready

- ASME Code, Section VIII Suction scrubber. 316 SS mist eliminator, condensate level controls with pump for rated flows & pressures

- Gas after-cooler with 30°F approach to ambient and a closed loop compressor jacket water cooling heat exchanger assembly

- CVR-M’s skid and enclosure are designed for harsh oil field conditions

- Wiring per NEC Class I, Div. II, Class B, C, & D on all electrical components for safe operation

- Unit Control Panel per NEC Class I, Division II, Class B,C, & D w/ TESCORP’s vapor recovery logic, controls and DCS comm. port

- Complete force-feed lubrication system including a 15 gal. oil storage reservoir, progressive flow type divider block, manifold & filter. Controls include flow indicators & monitors

- Motor starters and/or VFD drives are available for all accessary motors

- The CVR-M Vapor Recovery Unit utilizes a single-stage rotary vane compressor with minimal once-through oil lubrication. This eliminates the damages associated with liquid contamination of the lubrication and maintains temperatures in excess of the gas “dew-point”